When it comes to metals, we're heavyweights.

We know our metal—carbon, stainless, mild, alloy, galvanized, aluminum, brass, bronze, copper—you name it. And if you’re requesting hot-rolled carbon steel or cold-rolled carbon and galvanized steel, our quality steel products and cut-to-length systems and processing will leave you cheering. We'll deliver exactly what you need "just-in-time", too.

-

Angles—Bar Sizes

Stock Lengths 20', 30', & 40' as indicated

Size In Inches Estimated Weight, Lbs. A B C Per Foot 20-Ft. Length 30-Ft. Length 40-Ft. Length 1/2 1/2 1/8 .38 7.6 11.4 — 5/8 5/8 1/8 .48 9.6 14.4 — 3/4 3/4 1/8 .59 11.8 17.7 — 1 1 1/8 .80 16.0 24.0 32.0 3/16 1.16 23.2 34.8 46.4 1/4 1.49 29.8 44.7 59.6 1 1/4 1 1/4 1/8 1.01 20.2 30.3 40.4 3/16 1.48 29.6 44.4 59.2 1/4 1.92 38.4 57.6 76.8 1 3/8 7/8 3/16 1.32 26.4 39.6 52.8 1 1/2 1 1/4 3/16 1.64 32.8 49.2 65.6 1 1/2 1 1/2 3/16 1.80 36.0 54.0 72.0 1/4 2.34 46.8 70.2 93.6 1 3/4 1 1/4 3/16 1.80 36.0 54.0 72.0 1/4 2.34 46.8 70.2 93.6 1 3/4 1 3/4 1/4 2.77 55.4 83.1 110.8 2 1 1/2 1/8 1.44 28.8 43.2 57.6 3/16 2.12 42.4 63.6 84.8 1/4 2.77 55.4 83.1 110.8 2 2 1/8 1.65 33.0 49.5 66.0 3/16 2.44 48.8 73.2 97.6 1/4 3.19 63.8 95.7 127.6 3/8 4.70 94.0 141.0 188.0 2 1/2 1 1/2 3/16 2.44 48.8 73.2 97.6 1/4 3.19 63.8 95.7 127.6 2 1/2 2 3/16 2.75 55.0 82.5 110.0 1/4 3.62 72.4 108.6 144.8 2 1/2 2 1/2 3/16 3.07 61.4 92.1 122.8 1/4 4.10 82.0 123.0 164.0 5/16 5.00 100.0 150.0 200.0 3/8 5.90 118.0 177.0 236.0

-

Angles—Structural Sizes

Stocked in Lengths up to 60'.

Size in Inches Estimated Weight, Lbs. A B C Per Foot 20-Ft. Length 30-Ft. Length 40-Ft. Length 60-Ft. Length 3 2 3/16 3.07 61 92 123 184 1/4 4.1 82 123 164 246 3/8 5.9 118 177 236 354 3 2 1/2 1/4 4.5 90 135 180 270 5/16 5.6 112 168 224 336 3/8 6.6 132 198 264 396 3 3 3/16 3.71 74 111 148 223 1/4 4.9 98 147 196 294 5/16 6.1 122 183 244 366 3/8 7.2 144 216 288 432 1/2 9.4 188 282 376 564 3 1/2 2 1/2 1/4 4.9 98 147 196 294 3/8 7.2 144 216 288 432 3 1/2 3 1/4 5.4 108 162 216 324 3/8 7.9 158 237 316 474 3 1/2 3 1/2 1/4 5.8 116 174 232 348 5/16 7.2 144 216 288 432 3/8 8.5 170 255 340 510 4 3 1/4 5.8 116 174 232 348 5/16 7.2 144 216 288 432 3/8 8.5 170 255 340 510 1/2 11.1 222 333 444 666 4 3 1/2 5/16 7.7 154 231 308 462 3/8 9.1 182 273 364 546 1/2 11.9 238 357 476 714 4 4 1/4 6.6 132 198 264 396 5/16 8.2 164 246 328 492 3/8 9.8 196 294 392 588 1/2 12.8 256 384 512 768 5 3 1/4 6.6 132 198 264 396 5/16 8.2 164 246 328 492 3/8 9.8 196 294 392 588 5 3 1/2 1/4 7.0 140 210 280 420 5/16 8.7 174 261 348 522 3/8 10.4 208 312 416 624 1/2 13.6 272 408 544 816 5 5 5/16 10.3 206 309 412 618 3/8 12.3 246 369 492 738 1/2 16.2 324 486 648 972 6 3 1/2 1/4 7.9 158 237 316 474 5/16 9.8 196 294 392 588 3/8 11.7 234 351 468 702 6 4 5/16 10.3 206 309 412 618 3/8 12.3 246 369 492 738 1/2 16.2 324 486 648 972 6 6 5/16 12.4 248 372 496 744 3/8 14.9 298 447 596 894 1/2 19.6 392 588 784 1176 8 4 1/2 19.6 392 588 784 1176 8 6 1/2 23.0 460 690 920 1380 8 8 5/8 32.7 654 981 1308 1962

-

Rounds

<

Size in Inches Weight in Pounds Per Inch Per Foot 12-Ft. Bar 20-Ft. Bar 1/4 .0139 .167 2.01 3.34 5/16 .0218 .261 3.13 5.22 3/8 .0313 .376 4.51 7.52 13/32 .0368 .441 5.29 8.82 7/16 .0426 .512 6.14 10.23 15/32 .0489 .587 7.05 11.75 31/64 .0523 .627 7.53 12.54 1/2 .0557 .668 8.02 13.36 17/32 .0629 .754 9.05 15.09 9/16 .0705 .846 10.15 16.91 19/32 .0785 .942 11.31 18.85 39/64 .0827 .993 11.91 19.85 5/8 .0870 1.044 12.53 20.88 41/64 .0914 1.097 13.16 21.94 21/32 .0959 1.151 13.81 23.02 11/16 .1053 1.263 15.16 25.27 23/32 .1151 1.381 16.57 27.62 47/64 .1201 1.442 17.30 28.83 3/4 .1253 1.504 18.04 30.07 49/64 .1306 1.567 18.80 31.34 25/32 .1359 1.631 19.58 32.63 13/16 .1470 1.765 21.17 35.29 27/32 .1586 1.903 22.83 38.06 55/64 .1645 1.974 23.69 39.48 7/8 .1705 2.046 24.56 40.93 29/32 .1829 2.195 26.34 43.90 15/16 .1958 2.349 28.19 46.98 31/32 .2090 2.508 30.10 50.17 63/64 .2158 2.590 31.08 51.80 1 .2227 2.673 32.07 53.46 1 1/64 .2294 2.752 33.03 55.05 1 1/32 .2369 2.843 34.11 56.85 1 1/16 .2515 3.017 36.21 60.35 1 1/8 .2819 3.383 40.59 67.66 1 3/16 .3141 3.769 45.23 75.38 1 1/4 .3480 4.176 50.12 83.53 1 5/16 .3837 4.604 55.25 92.09 1 3/8 .4211 5.053 60.64 101.1 1 7/16 .4603 5.523 66.28 110.5 1 1/2 .5012 6.014 72.17 120.3 1 9/16 .5438 6.526 78.31 130.5 1 5/8 .5882 7.058 84.70 141.2 1 11/16 .6343 7.612 91.34 152.2 1 3/4 .6821 8.186 98.23 163.7 1 13/16 .7317 8.781 105.4 175.6 1 7/8 .7831 9.397 112.8 187.9 1 15/16 .8361 10.03 120.4 200.7 2 .8910 10.69 128.3 213.8 2 1/16 .9475 11.37 136.4 227.4 2 1/8 1.006 12.07 144.8 241.4 2 3/16 1.066 12.79 153.5 255.8 2 1/4 1.128 13.53 162.4 270.6 2 5/16 1.191 14.29 171.5 285.9 2 3/8 1.256 15.08 180.9 301.5 2 7/16 1.323 15.88 190.6 317.6 2 1/2 1.392 16.71 200.5 334.1 2 9/16 1.463 17.55 210.6 351.0 2 5/8 1.535 18.42 221.0 368.4 2 11/16 1.609 19.31 231.7 386.1 2 3/4 1.684 20.21 242.6 404.3 2 13/16 1.762 21.14 253.7 422.9 2 7/8 1.841 22.09 265.1 441.9 2 15/16 1.922 23.06 276.8 461.3 3 2.005 24.06 288.7 481.1 3 1/16 2.089 25.07 300.8 501.4 3 1/8 2.175 26.10 313.2 522.0 3 3/16 2.263 27.16 325.9 543.1 3 1/4 2.353 28.23 338.8 564.6 3 5/16 2.444 29.33 351.9 586.6 3 3/8 2.537 30.45 365.3 608.9 3 7/16 2.632 31.58 379.0 631.7 3 1/2 2.729 32.74 392.9 654.8 3 9/16 2.827 33.92 407.1 678.4 3 5/8 2.927 35.12 421.5 702.5 3 11/16 3.029 36.35 436.1 726.9 3 3/4 3.132 37.59 451.0 751.7 3 13/16 3.238 38.85 466.2 777.0 3 7/8 3.345 40.14 481.6 802.7 3 15/16 3.453 41.44 497.3 828.8 4 3.564 42.77 513.2 855.3 4 1/8 3.790 45.48 545.8 909.6 4 3/16 3.906 46.87 562.4 937.4 4 1/4 4.023 48.28 579.3 965.6 4 5/16 4.142 49.71 596.5 994.2 4 3/8 4.263 51.16 613.9 1023 4 7/16 4.386 52.63 631.6 1053 4 1/2 4.510 54.13 649.5 1083 4 9/16 4.637 55.64 667.7 1113 4 5/8 4.765 57.18 686.1 1143 4 11/16 4.894 58.73 704.8 1175 4 3/4 5.026 60.31 723.7 1206 4 7/8 5.294 63.52 762.3 1270 4 15/16 5.430 65.16 781.9 1303 5 5.569 66.82 801.9 1336 5 1/8 5.850 70.21 842.4 1404 5 1/4 6.139 73.67 884.0 1473 5 3/8 6.435 77.22 926.6 1544 5 7/16 6.586 79.03 948.3 1581 5 1/2 6.738 80.86 970.2 1617 5 5/8 7.048 84.57 1015 1691 5 3/4 7.364 88.37 1060 1767 5 15/16 7.852 94.23 1131 1885 6 8.019 96.22 1155 1924 6 1/4 8.701 104.4 1253 2088 6 1/2 9.411 112.9 1355 2259 6 3/4 10.15 121.8 1461 2436 7 10.91 131.0 1572 2619 7 1/4 11.71 140.5 1686 2810 7 1/2 12.53 150.4 1804 3007 7 3/4 13.38 160.5 1926 3211 8 14.26 171.1 2053 3421 8 1/4 15.16 181.9 2183 3638 8 1/2 16.09 193.1 2317 3862 8 3/4 17.05 204.6 2456 4093 9 18.04 216.5 2598 4330 9 1/4 19.06 228.7 2744 4574 9 1/2 20.10 241.2 2895 4824 9 3/4 21.17 254.1 3049 5082 10 22.27 267.3 3207 5346 10 1/4 23.40 280.8 3370 5616 10 1/2 24.56 294.7 3536 5894 10 3/4 25.74 308.9 3707 6178 11 26.95 323.4 3881 6468 11 1/2 29.46 353.5 4242 7070 12 32.07 384.9 4619 7698 12 1/2 34.80 417.6 5012 8353 13 37.64 451.7 5421 9034 13 1/2 40.59 487.1 5845 9743 14 43.66 523.9 6287 10478 15 50.12 601.4 7217 12028 16 57.02 684.3 8211 13685 16 1/2 60.64 727.7 8732 14554 17 64.37 772.5 9269 15449 17 1/2 68.21 818.6 9823 16371 18 72.17 866.0 10392 17320 19 80.41 964.9 11579 19298 20 89.10 1069 12830 21383 21 98.23 1179 14145 23575 22 107.8 1294 15524 25873 23 117.8 1414 16968 28280 24 128.3 1540 18475 30791 25 139.3 1671 20052 33420 26 150.6 1807 21682 36137 27 162.4 1949 23388 38980 28 174.6 2096 25152 41920 29 187.3 2248 26976 44960 30 200.5 2406 28872 48120 31 214.1 2569 30828 51380 32 228.1 2737 32844 54740 33 242.6 2911 34932 58220 34 257.5 3090 37080 61800 35 272.8 3274 39288 65480 36 288.7 3464 41568 69280 37 304.9 3659 43908 73180 38 321.7 3860 46320 77200 39 338.8 4065 48780 81300 40 356.4 4277 51324 85540

-

Squares

Size in Inches Weight in Pounds Per Inch Per Foot 12-Ft. Bar 20-Ft. Bar 1/8 .0044 .053 .64 1.06 3/16 .0100 .120 1.44 2.40 1/4 .0177 .213 2.55 4.25 5/16 .0277 .332 3.98 6.64 3/8 .0399 .479 5.74 9.57 7/16 .0543 .651 7.82 13.03 1/2 .0709 .851 10.21 17.02 9/16 .0897 1.077 12.92 21.54 5/8 .1108 1.329 15.95 26.59 11/16 .1340 1.609 19.30 32.17 3/4 .1595 1.914 22.97 38.29 13/16 .1872 2.247 26.96 44.93 7/8 .2171 2.606 31.27 52.11 15/16 .2493 2.991 35.89 59.82 1 .2836 3.403 40.84 68.06 1 1/16 .3202 3.842 46.10 76.84 1 1/8 .3589 4.307 51.69 86.14 1 3/16 .3999 4.799 57.59 95.98 1 1/4 .4431 5.381 63.81 106.4 1 5/16 .4885 5.863 70.36 117.3 1 3/8 .5362 6.434 77.21 128.7 1 1/2 .6381 7.657 91.89 153.1 1 9/16 .6924 8.309 99.71 166.2 1 5/8 .7489 8.987 107.8 179.7 1 3/4 .8685 10.42 125.1 208.4 1 7/8 .9970 11.96 143.6 239.3 2 1.134 13.61 163.4 272.3 2 1/8 1.281 15.37 184.4 307.4 2 1/4 1.436 17.23 206.7 344.6 2 3/8 1.600 19.20 230.4 383.9 2 1/2 1.773 21.27 255.2 425.4 2 5/8 1.954 23.45 281.4 469.0 2 3/4 2.145 25.74 308.8 514.7 2 7/8 2.344 28.13 337.6 562.6 3 2.552 30.63 367.5 612.6 3 1/4 2.996 35.95 431.4 718.9 3 1/2 3.474 41.69 500.3 833.8 3 3/4 3.988 47.86 574.3 957.2 4 4.538 54.45 653.4 1089 4 1/4 5.123 61.47 737.6 1229 4 1/2 5.743 68.91 827.0 1378 4 3/4 6.399 76.78 921.4 1536 5 7.090 85.08 1021 1702 5 1/2 8.579 102.9 1235 2059 6 10.21 122.5 1470 2450 7 13.90 166.8 2001 3335 8 18.15 217.8 2614 4356 9 22.97 275.6 3308 5512 10 28.36 340.3 4084 6808 12 40.84 490.0 5880 9800 14 55.60 667.2 8004 13340 16 72.60 871.2 10456 17424 18 91.88 1102 13232 22048

-

Flats

Size in Inches Weight in Pounds Per Inch Per Foot 12-Ft. Bar 20-Ft. Bar 1/16 x 1/4 .0044 .053 .64 1.06 1/16 x 3/8 .0066 .080 .96 1.60 1/16 x 1/2 .0089 .106 1.28 2.13 1/16 x 5/8 .0111 .133 1.60 2.66 1/16 x 3/4 .0133 .160 1.91 3.19 1/16 x 7/8 .0155 .186 2.23 3.72 1/16 x 1 .0177 .213 2.55 4.25 1/16 x 1 1/8 .0199 .239 2.87 4.79 1/16 x 1 1/4 .0222 .266 3.19 5.32 1/16 x 1 1/2 .0266 .319 3.83 6.38 1/16 x 1 3/4 .0310 .372 4.47 7.45 1/16 x 2 .0355 .425 5.11 8.51 1/16 x 2 1/2 .0443 .532 6.38 10.64 1/16 x 3 .0532 .638 7.66 12.76 3/32 x 3/8 .0100 .120 1.44 2.39 3/32 x 1/2 .0133 .160 1.91 3.19 3/32 x 5/8 .0166 .199 2.39 3.99 3/32 x 3/4 .0199 .239 2.87 4.79 3/32 x 7/8 .0233 .279 3.35 5.58 3/32 x 1 .0266 .319 3.83 6.38 3/32 x 1 1/8 .0299 .359 4.31 7.18 3/32 x 1 1/4 .0332 .399 4.79 7.98 3/32 x 1 1/2 .0399 .479 5.74 9.57 3/32 x 1 3/4 .0465 .558 6.70 11.17 3/32 x 2 .0532 .638 7.66 12.76 3/32 x 2 1/2 .0665 .798 9.57 15.95 3/32 x 3 .0798 .957 11.49 19.14 1/8 x 3/16 .0066 .080 .96 1.60 1/8 x 1/4 .0089 .106 1.28 2.13 1/8 x 5/16 .0111 .133 1.60 2.66 1/8 x 3/8 .0133 .160 1.91 3.19 1/8 x 1/2 .0177 .213 2.55 4.25 1/8 x 5/8 .0222 .266 3.19 5.32 1/8 x 3/4 .0266 .319 3.83 6.38 1/8 x 7/8 .0310 .372 4.47 7.45 1/8 x 1 .0355 .425 5.11 8.51 1/8 x 1 1/8 .0399 .479 5.74 9.57 1/8 x 1 1/4 .0443 .532 6.38 10.64 1/8 x 1 1/2 .0532 .638 7.66 12.76 1/8 x 1 3/4 .0620 .745 8.93 14.89 1/8 x 2 .0709 .851 10.21 17.02 1/8 x 2 1/4 .0798 .957 11.49 19.14 1/8 x 2 1/2 .0886 1.064 12.76 21.27 1/8 x 2 3/4 .0975 1.170 14.04 23.40 1/8 x 3 .1064 1.276 15.31 25.52 1/8 x 3 1/2 .1241 1.489 17.87 29.78 1/8 x 4 .1418 1.702 20.42 34.03 1/8 x 4 1/2 .1595 1.914 22.97 38.29 1/8 x 5 .1773 2.127 25.52 42.54 1/8 x 6 .2127 2.552 30.63 51.05 1/8 x 8 .2836 3.403 40.84 68.06 1/8 x 10 .3545 4.254 51.05 85.08 1/8 x 12 .4254 5.105 61.26 102.1 3/16 x 1/4 .0133 .160 1.91 3.19 3/16 x 5/16 .0166 .199 2.39 3.99 3/16 x 3/8 .0199 .239 2.87 4.79 3/16 x 7/16 .0233 .279 3.35 5.58 3/16 x 1/2 .0266 .319 3.83 6.38 3/16 x 5/8 .0332 .399 4.79 7.98 3/16 x 3/4 .0399 .479 5.74 9.57 3/16 x 7/8 .0465 .558 6.70 11.17 3/16 x 1 .0532 .638 7.66 12.76 3/16 x 1 1/8 .0598 .718 8.61 14.36 3/16 x 1 1/4 .0665 .798 9.57 15.95 3/16 x 1 3/8 .0731 .877 10.53 17.55 3/16 x 1 1/2 .0798 .957 11.49 19.14 3/16 x 1 3/4 .0931 1.117 13.40 22.33 3/16 x 2 .1064 1.276 15.31 25.52 3/16 x 2 1/4 .1196 1.436 17.23 28.71 3/16 x 2 1/2 .1329 1.595 19.14 31.91 3/16 x 2 3/4 .1462 1.755 21.06 35.10 3/16 x 3 .1595 1.914 22.97 38.29 3/16 x 3 1/2 .1861 2.233 26.80 44.67 3/16 x 4 .2127 2.552 30.63 51.05 3/16 x 4 1/2 .2393 2.871 34.46 57.43 3/16 x 5 .2659 3.191 38.29 63.81 3/16 x 6 .3191 3.829 45.94 76.57 3/16 x 8 .4254 5.105 61.26 102.1 3/16 x 10 .5318 6.381 76.57 127.6 3/16 x 12 .6381 7.657 91.89 153.1 1/4 x 5/16 .0222 .266 3.19 5.32 1/4 x 3/8 .0266 .319 3.83 6.38 1/4 x 7/16 .0310 .372 4.47 7.44 1/4 x 1/2 .0355 .425 5.11 8.51 1/4 x 9/16 .0399 .479 5.74 9.57 1/4 x 5/8 .0443 .532 6.38 10.64 1/4 x 3/4 .0532 .638 7.66 12.76 1/4 x 7/8 .0620 .745 8.93 14.89 1/4 x 1 .0709 .851 10.21 17.02 1/4 x 1 1/8 .0798 .957 11.49 19.14 1/4 x 1 1/4 .0886 1.064 12.76 21.27 1/4 x 1 3/8 .0975 1.170 14.04 23.40 1/4 x 1 1/2 .1064 1.276 15.31 25.52 1/4 x 1 5/8 .1152 1.383 16.59 27.65 1/4 x 1 3/4 .1241 1.489 17.87 29.78 1/4 x 2 .1418 1.702 20.42 34.03 1/4 x 2 1/4 .1595 1.914 22.97 38.29 1/4 x 2 1/2 .1773 2.127 25.52 42.54 1/4 x 2 3/4 .1950 2.340 28.08 46.79 1/4 x 3 .2127 2.552 30.63 51.05 1/4 x 3 1/4 .2304 2.765 33.18 55.30 1/4 x 3 1/2 .2482 2.978 35.73 59.56 1/4 x 3 3/4 .2659 3.191 38.29 63.81 1/4 x 4 .2836 3.403 40.84 68.06 1/4 x 4 1/2 .3191 3.829 45.94 76.57 1/4 x 4 3/4 .3368 4.041 48.49 80.82 1/4 x 5 .3545 4.254 51.05 85.08 1/4 x 5 1/2 .3900 4.679 56.15 93.59 1/4 x 6 .4254 5.105 61.26 102.1 1/4 x 6 1/2 .4609 5.530 66.36 110.6 1/4 x 7 .4963 5.956 71.47 119.1 1/4 x 8 .5672 6.806 81.68 136.1 1/4 x 9 .6381 7.657 91.88 153.1 1/4 x 10 .7090 8.508 102.1 170.2 1/4 x 12 .8508 10.21 122.5 204.2 5/16 x 3/8 .0332 .399 4.79 7.98 5/16 x 1/2 .0443 .532 6.38 10.64 5/16 x 5/8 .0554 .665 7.98 13.29 5/16 x 3/4 .0665 .798 9.57 15.95 5/16 x 7/8 .0775 .931 11.17 18.61 5/16 x 1 .0886 1.064 12.76 21.27 5/16 x 1 1/8 .0997 1.196 14.36 23.93 5/16 x 1 1/4 .1108 1.329 15.95 26.59 5/16 x 1 3/8 .1219 1.462 17.55 29.25 5/16 x 1 1/2 .1329 1.595 19.14 31.91 5/16 x 1 5/8 .1440 1.729 20.74 34.56 5/16 x 1 3/4 .1551 1.861 22.33 37.22 5/16 x 2 .1773 2.127 25.52 42.54 5/16 x 2 1/4 .1994 2.393 28.71 47.86 5/16 x 2 1/2 .2216 2.659 31.91 53.18 5/16 x 2 3/4 .2437 2.925 35.10 58.50 5/16 x 3 .2659 3.191 38.29 63.81 5/16 x 3 1/2 .3102 3.722 44.68 74.45 5/16 x 4 .3545 4.254 51.05 85.08 5/16 x 4 1/2 .3988 4.786 57.43 95.72 5/16 x 5 .4431 5.318 63.81 106.4 5/16 x 5 1/2 .4874 5.849 70.19 117.0 5/16 x 6 .5318 6.381 76.57 127.6 5/16 x 7 .6204 7.445 89.33 148.9 5/16 x 8 .7090 8.508 102.1 170.2 5/16 x 10 .8863 10.64 127.6 212.7 5/16 x 12 1.064 12.76 153.1 255.2 3/8 x 7/16 .0465 .558 6.70 11.17 3/8 x 1/2 .0532 .638 7.66 12.76 3/8 x 5/8 .0665 .798 9.57 15.95 3/8 x 3/4 .0798 .957 11.49 19.14 3/8 x 7/8 .0931 1.117 13.40 22.33 3/8 x 1 .1064 1.276 15.31 25.52 3/8 x 1 1/8 .1196 1.436 17.23 28.71 3/8 x 1 1/4 .1329 1.595 19.14 31.91 3/8 x 1 3/8 .1462 1.755 21.06 35.10 3/8 x 1 1/2 .1595 1.914 22.97 38.29 3/8 x 1 5/8 .1728 2.074 24.89 41.48 3/8 x 1 3/4 .1861 2.233 26.80 44.67 3/8 x 2 .2127 2.552 30.63 51.05 3/8 x 2 1/4 .2393 2.871 34.46 57.43 3/8 x 2 1/2 .2659 3.191 38.29 63.81 3/8 x 2 3/4 .2925 3.510 42.11 70.19 3/8 x 3 .3191 3.829 45.94 76.57 3/8 x 3 1/4 .3436 4.148 49.77 82.95 3/8 x 3 3/8 .3589 4.307 51.69 86.14 3/8 x 3 1/2 .3722 4.467 53.60 89.33 3/8 x 3 3/4 .3988 4.786 57.43 95.72 3/8 x 4 .4254 5.105 61.26 102.1 3/8 x 4 1/4 .4520 5.424 65.09 108.5 3/8 x 4 1/2 .4786 5.743 68.91 114.9 3/8 x 5 .5318 6.381 76.57 127.6 3/8 x 5 1/2 .5849 7.019 84.23 140.4 3/8 x 6 .6381 7.657 91.89 153.1 3/8 x 6 1/2 .6913 8.295 99.54 165.9 3/8 x 7 .7445 8.933 107.2 178.7 3/8 x 8 .8508 10.21 122.5 204.2 3/8 x 9 .9572 11.49 137.9 229.8 3/8 x 10 1.064 12.76 153.1 255.2 3/8 x 12 1.276 15.31 183.8 306.3 7/16 x 1/2 .0620 .745 8.93 14.89 7/16 x 5/8 .0775 .931 11.17 18.61 7/16 x 3/4 .0931 1.117 13.40 22.33 7/16 x 7/8 .1086 1.303 15.63 26.06 7/16 x 1 .1241 1.489 17.87 29.78 7/16 x 1 1/4 .1551 1.861 22.33 37.22 7/16 x 1 1/2 .1861 2.333 26.80 44.67 7/16 x 1 3/4 .2171 2.606 31.27 52.11 7/16 x 2 .2482 2.978 35.73 59.56 7/16 x 2 1/4 .2792 3.350 40.20 67.00 7/16 x 2 1/2 .3102 3.722 44.67 74.45 7/16 x 3 .3722 4.467 53.60 89.33 7/16 x 3 1/2 .4343 5.211 62.53 104.2 7/16 x 4 .4963 5.956 71.47 119.1 7/16 x 5 .6204 7.445 89.33 148.9 7/16 x 6 .7445 8.933 107.2 178.7 1/2 x 5/8 .0886 1.064 12.76 21.27 1/2 x 3/4 .1064 1.276 15.31 25.52 1/2 x 7/8 .1241 1.489 17.87 29.78 1/2 x 1 .1418 1.702 20.42 34.03 1/2 x 1 1/8 .1595 1.914 22.97 38.29 1/2 x 1 1/4 .1773 2.127 25.52 42.54 1/2 x 1 3/8 .1950 2.340 28.08 46.79 1/2 x 1 1/2 .2127 2.552 30.63 51.05 1/2 x 1 5/8 .2304 2.765 33.18 55.30 1/2 x 1 3/4 .2482 2.978 35.73 59.56 1/2 x 2 .2836 3.403 40.84 68.06 1/2 x 2 1/4 .3191 3.829 45.94 76.57 1/2 x 2 1/2 .3545 4.254 51.05 85.08 1/2 x 2 3/4 .3900 4.679 56.15 93.59 1/2 x 3 .4254 5.105 61.26 102.1 1/2 x 3 1/4 .4609 5.530 66.36 110.6 1/2 x 3 1/2 .4963 5.956 71.47 119.1 1/2 x 3 3/4 .5813 6.381 76.57 127.6 1/2 x 4 .5672 6.806 81.68 136.1 1/2 x 4 1/4 .6027 7.232 86.78 144.6 1/2 x 4 1/2 .6381 7.657 91.89 153.1 1/2 x 4 3/4 .6736 8.083 97.00 161.7 1/2 x 5 .7090 8.508 102.1 170.2 1/2 x 5 1/2 .7799 9.359 112.3 187.2 1/2 x 6 .8508 10.21 122.5 204.2 1/2 x 6 1/2 .9217 11.06 132.7 221.2 1/2 x 7 .9926 11.91 142.9 238.2 1/2 x 8 1.134 13.61 163.4 272.3 1/2 x 9 1.276 15.31 183.8 306.3 1/2 x 10 1.418 17.02 204.2 340.3 1/2 x 12 1.702 20.42 245.0 408.4 5/8 x 3/4 .1329 1.595 19.14 31.91 5/8 x 7/8 .1551 1.861 22.33 37.22 5/8 x 1 .1773 2.127 25.52 42.54 5/8 x 1 1/8 .1994 2.393 28.71 47.86 5/8 x 1 1/4 .2216 2.659 31.91 53.18 5/8 x 1 3/8 .2437 2.925 35.10 58.49 5/8 x 1 1/2 .2659 3.191 38.29 63.81 5/8 x 1 5/8 .2880 3.456 41.47 69.12 5/8 x 1 3/4 .3102 3.722 44.67 74.45 5/8 x 2 .3545 4.254 51.05 85.08 5/8 x 2 1/4 .3988 4.786 57.43 95.72 5/8 x 2 1/2 .4431 5.318 63.81 106.4 5/8 x 2 3/4 .4874 5.849 70.19 117.0 5/8 x 3 .5318 6.381 76.57 127.6 5/8 x 3 1/4 .5761 6.913 82.95 138.3 5/8 x 3 1/2 .6204 7.445 89.33 148.9 5/8 x 4 .7090 8.508 102.1 170.2 5/8 x 4 1/2 .7976 9.572 114.9 191.4 5/8 x 5 .8863 10.64 127.6 212.7 5/8 x 5 1/2 .9749 11.70 140.4 234.0 5/8 x 6 1.064 12.76 153.1 255.2 5/8 x 7 1.241 14.89 178.7 297.8 5/8 x 8 1.418 17.02 204.2 340.3 5/8 x 10 1.773 21.27 255.2 425.4 5/8 x 12 2.127 25.52 306.3 510.5 3/4 x 7/8 .1861 2.233 26.80 44.67 3/4 x 1 .2127 2.552 30.63 51.05 3/4 x 1 1/8 .2393 2.871 34.46 57.43 3/4 x 1 1/4 .2659 3.191 38.29 63.81 3/4 x 1 3/8 .2925 3.510 42.11 70.19 3/4 x 1 1/2 .3191 3.829 45.94 76.57 3/4 x 1 5/8 .3456 4.148 49.77 82.95 3/4 x 1 3/4 .3722 4.467 53.60 89.33 3/4 x 2 .4254 5.105 61.26 102.1 3/4 x 2 1/4 .4786 5.743 68.91 114.9 3/4 x 2 1/2 .5318 6.381 76.57 127.6 3/4 x 2 3/4 .5849 7.019 84.23 140.4 3/4 x 3 .6381 7.657 91.89 153.1 3/4 x 3 1/4 .6913 8.295 99.54 165.9 3/4 x 3 1/2 .7445 8.933 107.2 178.7 3/4 x 3 3/4 .7976 9.572 114.9 191.4 3/4 x 4 .8508 10.21 122.5 204.2 3/4 x 4 1/2 .9572 11.49 137.8 229.7 3/4 x 5 1.064 12.76 153.1 255.2 3/4 x 5 1/2 1.170 14.04 168.5 280.8 3/4 x 6 1.276 15.31 183.8 306.3 3/4 x 7 1.489 17.87 214.4 357.3 3/4 x 8 1.702 20.42 245.0 408.4 3/4 x 9 1.914 22.97 275.7 459.4 3/4 x 10 2.127 25.52 306.3 510.5 3/4 x 12 2.552 30.63 367.5 612.6 7/8 x 1 1/8 .2482 2.978 35.73 59.56 7/8 x 1 1/8 .2792 3.350 40.20 67.00 7/8 x 1 1/4 .3102 3.722 44.67 74.45 7/8 x 1 3/8 .3412 4.094 49.13 81.89 7/8 x 1 1/2 .3722 4.467 53.60 89.33 7/8 x 1 3/4 .4343 5.211 62.53 104.2 7/8 x 2 .4963 5.956 71.47 119.1 7/8 x 2 1/4 .5583 6.700 80.40 134.0 7/8 x 2 1/2 .6204 7.445 89.33 148.9 7/8 x 2 3/4 .6824 8.189 98.27 163.8 7/8 x 3 .7445 8.933 107.2 178.7 7/8 x 3 1/2 .8685 10.42 125.1 208.4 7/8 x 4 .9926 11.91 142.9 238.2 7/8 x 4 1/2 1.117 13.40 160.8 268.0 7/8 x 5 1.241 14.89 178.7 297.8 7/8 x 6 1.489 17.87 214.4 357.3 7/8 x 7 1.737 20.84 250.1 416.9 7/8 x 8 1.985 23.82 285.9 476.4 7/8 x 10 2.482 29.78 357.4 595.6 7/8 x 12 2.975 35.73 428.4 714.7 1 x 1 1/8 .3191 3.829 45.94 76.57 1 x 1 1/4 .3545 4.254 51.05 85.08 1 x 1 3/8 .3900 4.679 56.15 93.59 1 x 1 1/2 .4254 5.105 61.26 102.1 1 x 1 5/8 .4609 5.530 66.36 110.6 1 x 1 3/4 .4963 5.956 71.47 119.1 1 x 2 .5672 6.806 81.68 136.1 1 x 2 1/4 .6381 7.657 91.89 153.1 1 x 2 1/2 .7090 8.508 102.1 170.2 1 x 2 3/4 .7799 9.359 112.3 187.2 1 x 3 .8508 10.21 122.5 204.2 1 x 3 1/4 .9217 11.06 132.7 221.2 1 x 3 1/2 .9926 11.91 142.9 238.2 1 x 4 1.134 13.61 163.4 272.3 1 x 4 1/2 1.276 15.31 183.8 306.3 1 x 5 1.418 17.02 204.2 340.3 1 x 5 1/2 1.560 18.72 224.6 374.4 1 x 6 1.702 20.42 245.0 408.4 1 x 6 1/2 1.843 22.12 265.4 442.4 1 x 7 1.985 23.82 285.9 476.4 1 x 8 2.269 27.23 326.7 544.4 1 x 9 2.552 30.63 367.5 612.6 1 x 10 2.836 34.03 408.4 680.6 1 x 11 3.120 37.44 449.3 748.8 1 x 12 3.403 40.84 490.1 816.8 1 1/8 x 1 1/4 .3988 4.786 57.43 95.72 1 1/8 x 1 1/2 .4786 5.743 68.92 114.9 1 1/8 x 1 3/4 .5583 6.700 80.40 134.0 1 1/8 x 2 .6381 7.657 91.89 153.1 1 1/8 x 2 1/4 .7179 8.614 103.4 172.3 1 1/8 x 2 1/2 .7976 9.572 114.9 191.4 1 1/8 x 3 .9572 11.49 137.8 229.7 1 1/8 x 4 1.276 15.31 183.8 306.3 1 1/8 x 5 1.595 19.14 229.7 382.9 1 1/8 x 6 1.914 22.97 275.7 459.4 1 1/4 x 1 3/8 .4874 5.849 70.19 117.0 1 1/4 x 1 1/2 .5318 6.381 76.57 127.6 1 1/4 x 1 5/8 .5761 6.913 82.96 138.3 1 1/4 x 1 3/4 .6204 7.445 89.33 148.9 1 1/4 x 2 .7090 8.508 102.1 170.2 1 1/4 x 2 1/4 .7976 9.572 114.9 191.4 1 1/4 x 2 1/2 .8863 10.64 127.6 221.7 1 1/4 x 2 3/4 .9749 11.70 140.4 234.0 1 1/4 x 3 1.064 12.76 153.1 255.2 1 1/4 x 3 1/4 1.152 13.82 165.8 276.4 1 1/4 x 3 1/2 1.241 14.89 178.7 297.8 1 1/4 x 3 3/4 1.329 15.95 191.4 319.0 1 1/4 x 4 1.418 17.02 204.2 340.3 1 1/4 x 4 1/2 1.595 19.14 229.7 382.9 1 1/4 x 5 1.773 21.27 255.2 425.4 1 1/4 x 5 1/2 1.950 23.40 280.8 467.9 1 1/4 x 6 2.127 25.52 306.3 510.5 1 1/4 x 7 2.482 29.78 357.3 595.6 1 1/4 x 8 2.836 34.03 408.4 680.6 1 1/4 x 9 3.191 38.29 459.5 765.8 1 1/4 x 10 3.545 42.54 510.5 850.8 1 1/4 x 12 4.254 51.05 612.6 1021 1 1/2 x 1 5/8 .6913 8.295 99.54 165.9 1 1/2 x 1 3/4 .7445 8.933 107.2 178.7 1 1/2 x 2 .8508 10.21 122.5 204.2 1 1/2 x 2 1/4 .9572 11.49 137.8 229.7 1 1/2 x 2 1/2 1.064 12.76 153.1 255.2 1 1/2 x 2 3/4 1.170 14.04 168.5 280.8 1 1/2 x 3 1.276 15.31 183.8 306.3 1 1/2 x 3 1/4 1.383 16.59 199.1 331.8 1 1/2 x 3 1/2 1.489 17.87 214.4 357.3 1 1/2 x 4 1.702 20.42 245.0 408.4 1 1/2 x 4 1/2 1.914 22.97 275.7 459.4 1 1/2 x 5 1/2 2.340 28.08 336.9 561.5 1 1/2 x 6 2.552 30.63 367.5 612.6 1 1/2 x 7 2.978 35.73 428.8 714.7 1 1/2 x 8 3.403 40.84 490.1 816.8 1 1/2 x 9 3.829 45.94 551.3 918.8 1 1/2 x 10 4.254 51.05 612.6 1021 1 1/2 x 12 5.105 61.26 735.1 1225 1 3/4 x 2 .9926 11.91 142.9 238.2 1 3/4 x 2 1/4 1.117 13.40 160.8 268.0 1 3/4 x 2 1/2 1.241 14.89 178.7 297.8 1 3/4 x 2 3/4 1.365 16.38 196.5 327.6 1 3/4 x 3 1.489 17.87 214.4 357.3 1 3/4 x 3 1/2 1.737 20.84 250.1 416.9 1 3/4 x 4 1.985 23.82 285.9 476.4 1 3/4 x 4 1/2 2.233 26.80 321.6 536.0 1 3/4 x 5 2.482 29.78 357.3 595.6 1 3/4 x 6 2.978 35.73 428.8 714.7 1 3/4 x 8 3.970 47.64 571.7 952.8 1 3/4 x 9 4.467 53.60 643.2 1072 1 3/4 x 10 4.963 59.56 714.7 1191 2 x 2 1/4 1.276 15.31 183.8 306.3 2 x 2 1/2 1.418 17.02 204.2 340.3 2 x 2 3/4 1.560 18.72 224.6 374.4 2 x 3 1.702 20.42 245.0 408.4 2 x 3 1/4 1.843 22.12 265.4 442.4 2 x 3 1/2 1.985 23.82 285.9 476.4 2 x 3 3/4 2.127 25.52 306.2 510.4 2 x 4 2.269 27.23 326.7 544.5 2 x 4 1/2 2.552 30.63 367.5 612.6 2 x 5 2.836 34.03 408.4 680.6 2 x 5 1/2 3.120 37.44 449.3 748.8 2 x 6 3.403 40.84 490.1 816.8 2 x 7 3.970 47.64 571.7 952.9 2 x 8 4.538 54.45 653.4 1089 2 x 10 5.672 68.06 816.8 1361 2 x 12 6.806 81.68 980.1 1634 2 1/2 x 2 3/4 1.949 23.40 280.8 468.0 2 1/2 x 3 2.127 25.52 306.3 510.5 2 1/2 x 3 1/2 2.482 29.78 357.3 595.6 2 1/2 x 4 2.836 34.03 408.4 680.6 2 1/2 x 4 1/2 3.191 38.29 459.4 765.7 2 1/2 x 5 3.545 42.54 510.5 850.8 2 1/2 x 5 1/2 3.900 46.79 561.5 935.8 2 1/2 x 6 4.254 51.05 612.6 1021 2 1/2 x 7 4.963 59.56 714.7 1191 2 1/2 x 8 5.672 68.06 816.8 1361 2 1/2 x 9 6.381 76.57 918.9 1531 2 1/2 x 10 7.090 85.08 1021 1702 2 1/2 x 11 7.799 93.59 1123 1872 2 1/2 x 12 8.508 102.1 1225 2042 3 x 3 1/2 2.978 35.73 428.8 714.7 3 x 4 3.403 40.84 490.1 816.8 3 x 4 1/2 3.829 45.94 551.3 918.9 3 x 5 4.254 51.05 612.6 1021 3 x 6 5.105 61.26 735.1 1225 3 x 7 5.957 71.47 857.6 1429 3 x 8 6.806 81.68 980.1 1634 3 x 10 8.508 102.1 1225 2042 3 x 12 10.21 122.5 1470 2450

-

Standard ("I") Beams

Stocked in Lengths up to 60'.

AISI Designation A—Depth in Inches B—Flange Width Inches C—Web Thickness Inches Weight, Lbs. Per Foot 20-Ft. Length 30-Ft. Length 40-Ft. Length 60-Ft. Length S3 x 5.7 3 2.330 .170 5.7 114 171 228 342 S4 x 7.7 4 2.663 .193 7.7 154 231 308 462 S4 x 9.5 4 2.796 .326 9.5 190 285 380 570 S5 x 10 5 3.004 .214 10.0 200 300 400 600 S5 x 14.75 5 3.284 .494 14.75 295 443 590 885 S6 x 12.5 6 3.332 .232 12.5 250 375 500 750 S6 x 17.25 6 3.565 .465 17.25 345 518 690 1035 S7 x 15.3 7 3.662 .252 15.3 306 459 612 918 S7 x 20 7 3.860 .450 20.0 400 600 800 1200 S8 x 18.4 8 4.001 .271 18.4 368 552 736 1104 S8 x 23 8 4.171 .441 23.0 460 690 920 1380 S10 x 25.4 10 4.661 .311 25.4 508 762 1016 1524 S10 x 35 10 4.944 .594 35.0 700 1050 1400 2100 S12 x 31.8 12 5.000 .350 31.8 636 954 1272 1908 S12 x 35 12 5.078 .428 35.0 700 1050 1400 2100 S12 x 40.8 12 5.252 .462 40.8 816 1224 1632 2448 S12 x 50 12 5.477 .687 50.0 100 1500 2000 3000 S15 x 42.9 15 5.501 .411 42.9 858 1287 1716 2574 S15 x 50 15 5.640 .550 50.0 1000 1500 2000 3000 S18 x 54.7 18 6.001 .461 54.7 1094 1641 2188 3282 S18 x 70 18 6.251 .711 70.0 1400 2100 2800 4200 S20 x 66 20 6.255 .505 66.0 1320 1980 2640 3960 S20 x 75 20 6.385 .635 75.0 1500 2250 3000 4500 S20 x 86 20 7.060 .660 86.0 1720 2580 3440 5160 S20 x 96 20 7.200 .800 96.0 1920 2880 3840 5760 S24 x 80 24 7.000 .500 80.0 1600 2400 3200 4800 S24 x 90 24 7.125 .625 90.0 1800 2700 3600 5400 S24 x 100 24 7.245 .745 100.0 2000 3000 4000 6000 S24 x 106 24.5 7.870 .620 106.0 2120 3180 4240 6360 S24 x 121 24.5 8.050 .800 121.0 2420 3630 4840 7260

-

Wide Flange (W) and Miscellaneous Shapes (M)

Stocked in Lengths up to 60'.

AISI Designation A—Depth in Inches B—Flange Width Inches C—Web Thickness Inches Weight, Lbs. Per Foot 20-Ft. Length 40-Ft. Length 60-Ft. Length W4 x 13.0 4.16 4.060 .280 13.0 260 520 780 M4 x 13.0 4.00 3.940 .254 13.0 260 520 780 W5 x 16.0 5.01 5.000 .240 16.0 320 640 960 M5 x 18.9 5.00 5.003 .316 18.9 378 756 1134 W5 x 19.0 5.15 5.030 .270 19.0 380 760 1140 M6 x 4.4 6.00 1.844 .114 4.4 88 176 264 W6 x 9.0 5.90 3.940 .170 9.0 180 360 540 W6 x 12.0 6.03 4.000 .230 12.0 240 480 720 W6 x 15.0 5.99 5.990 .230 15.0 300 600 900 W6 x 16.0 6.28 4.030 .260 16.0 320 640 960 W6 x 20.0 6.20 6.020 .260 20.0 400 800 1200 W6 x 25.0 6.38 6.080 .320 25.0 500 1000 1500 M8 x 6.5 8.00 2.281 .135 6.5 130 260 390 W8 x 10.0 7.89 3.940 .170 10.0 200 400 600 W8 x 13.0 7.99 4.000 .230 13.0 260 520 780 W8 x 15.0 8.11 4.015 .245 15.0 300 600 900 W8 x 18.0 8.14 5.250 .230 18.0 360 720 1080 W8 x 21.0 8.28 5.270 .250 21.0 420 840 1260 W8 x 24.0 7.93 6.495 .245 24.0 480 960 1440 W8 x 28.0 8.06 6.535 .285 28.0 560 1120 1680 W8 x 31.0 8.00 7.995 .285 31.0 620 1240 1860 W8 x 35.0 8.12 8.020 .310 35.0 700 1400 2100 W8 x 40.0 8.25 8.070 .360 40.0 800 1600 2400 W8 x 48.0 8.50 8.110 .400 48.0 960 1920 2880 W8 x 58.0 8.75 8.220 .510 58.0 1160 2320 3480 W8 x 67.0 9.00 8.280 .570 67.0 1340 2680 4020 M10 x 9.0 10.00 2.690 .157 9.0 180 360 540 W10 x 12.0 9.87 3.960 .190 12.0 240 480 720 W10 x 15.0 9.99 4.000 .230 15.0 300 600 900 W10 x 17.0 10.11 4.010 .240 17.0 340 680 1020 W10 x 19.0 10.24 4.020 .250 19.0 380 760 1140 W10 x 22.0 10.17 5.750 .240 22.0 440 880 1320 W10 x 26.0 10.33 5.770 .260 26.0 520 1040 1560 W10 x 30.0 10.47 5.810 .300 30.0 600 1200 1800 W10 x 33.0 9.73 7.960 .290 33.0 660 1320 1980 W10 x 39.0 9.92 7.985 .315 39.0 780 1560 2340 W10 x 45.0 10.10 8.020 .350 45.0 900 1800 2700 W10 x 49.0 9.98 10.000 .340 49.0 980 1960 2940 W10 x 54.0 10.09 10.030 .370 54.0 1080 2160 3240 W10 x 60.0 10.22 10.080 .420 60.0 1200 2400 3600 W10 x 68.0 10.40 10.130 .470 68.0 1360 2720 4080 W10 x 77.0 10.60 10.190 .530 77.0 1540 3080 4620 W10 x 88.0 10.84 10.265 .605 88.0 1760 3520 5280 W10 x 100.0 11.10 10.340 .680 100.0 2000 4000 6000

-

Channel—Bar Sizes

Stock Lengths 20' and 30'.

Size In Inches Estimated Weight, Lbs. A B C Per Foot 20-Ft. Length 30-Ft. Length 1 1/2 1/8 .84 16.8 25.2 1 1/4 1/2 1/8 1.01 20.2 30.3 1 1/2 1/2 1/8 1.12 22.4 33.6 1 1/2 3/4 1/8 1.17 23.4 35.1 2 1 1/8 1.78 35.6 53.4 2 1 3/16 2.57 51.4 77.1

-

Channel—Standard Structural Sizes

Stocked in Lengths up to 60'.

AISI Designation A—Depth in Inches B—Flange Width Inches C—Web Thickness Inches Weight, Lbs. Per Foot 20-Ft. Length 30-Ft. Length 40-Ft. Length 60-Ft. Length C3 x 3.5 C3 x 4.1 3 1.410 .170 4.1 82 123 164 246 C3 x 5 3 1.498 .258 5.0 100 150 200 300 C4 x 4.5 C4 x 5.4 4 1.584 .184 5.4 108 162 216 324 C4 x 7.25 4 1.721 .321 7.25 145 218 290 435 C5 x 6.7 5 1.750 .190 6.7 134 201 268 402 C6 x 8.2 6 1.920 .200 8.2 164 246 328 492 C6 x 10.5 6 2.034 .314 10.5 210 315 420 630 C6 x 13 6 2.157 .437 13.0 260 390 520 780 C7 x 9.8 7 2.090 .210 9.8 196 294 392 588 C8 x 11.5 8 2.260 .220 11.5 230 345 460 690 C8 x 13.75 8 2.343 .303 13.75 275 413 550 825 C10 x 15.3 10 2.600 .240 15.3 306 459 612 918 C12 x 20.7 12 2.942 .282 20.7 414 621 828 1242

-

Miscellaneous Channels—Structural Sizes

Stocked in Lengths up to 60'.

AISI Designation A—Depth in Inches B—Flange Width Inches C—Web Thickness Inches Weight, Lbs. Per Foot 20-Ft. Length 30-Ft. Length 40-Ft. Length 60-Ft. Length MC8 x 8.5 8 1.875 .188 8.5 170 255 340 510 MC10 x 8.4 10 1.500 .170 8.4 168 252 336 504

-

Expanded Metal

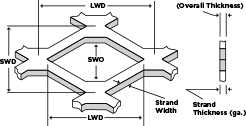

Expanded Metal is available in the "standard" pattern, where the strands and bonds are set at a sharp angle to the plane of the sheet. It is also available in the “flattened” pattern, where the material has been cold-rolled to bring the strands and bonds into the same plane. Flattened Expanded Metal is especially suited to welding because of its flat surface.

Expanded Metal offers the advantages of savings in weight and metal, free passage of light and air, and a decorative or ornamental effect. Structural applications include door panels, open partitions, window guards, enclosures, etc. Decorative applications include grilles, screens, panels, backgrounds, etc.

The width of the sheet is measured in the direction of the short dimension of the diamond. The length of the sheet is measured in the direction of the long dimension of the diamond. For additional information on applications, properties, and fabricating procedures, ask for our special pamphlet on Expanded Metal.

Standard

Flattened LEGEND

SWD—"Short way of diamond."

LWD—"Long way of diamond."

SWO—"Short way of opening."

LWO—"Long way of opening."

Strand Thickness—Equal to the thickness of the sheet of metal used.

Strand width—Amount of metal of a given thickness in one strand.Expanded Metal sheets are also available in STAINLESS STEEL, ALUMINUM, and other metals. Information on request.

-

Standard Expanded Metal

*Style Designation Width & Length (Inches) Thick. of Strand (Inches) Est. Wt., Lbs. Per Sq. Ft. Per Sheet 1/4" – #20 48 x 96 .036 .86 27.52 1/4" – #18 48 x 96 .048 1.14 36.48 1/2" – #20 36 x 96 .036 .43 10.32 48 x 96 " " 13.76 1/2" – #18 48 x 96 .048 .70 22.40 120 " " 28.00 72 x 96 " " 33.60 120 " " 42.00 1/2" – #16 48 x 96 .060 .86 27.52 120 " " 34.40 72 x 96 " " 41.28 120 " " 51.60 1/2" – #13 48 x 96 .092 1.47 47.04 120 " " 58.80 72 x 96 " " 70.56 3/4" – #16 48 x 96 .060 .54 17.28 120 " " 21.60 60 x 120 " " 27.00 72 x 96 " " 25.92 120 " " 32.40 144 " " 38.88 3/4" – #13 48 x 96 .092 .80 25.60 120 " " 32.00 72 x 96 " " 38.40 120 " " 48.00 96 x 120 " " 64.00 3/4" – #10 48 x 96 .092 1.20 38.40 120 " " 48.00 72 x 96 " " 57.60 120 " " 72.00 3/4" – #9 36 x 96 .134 1.80 43.20 120 " " 54.00 48 x 96 " " 57.60 120 " " 72.00 144 " " 86.40 60 x 96 " " 72.00 120 " " 90.00 72 x 96 " " 86.40 120 " " 108.00 144 " " 129.60 1" – #16 48 x 96 .060 .44 14.08 1 1/2" – #18 48 x 96 .048 .20 6.04 1 1/2" – #16 48 x 96 .060 .40 12.80 1 1/2" – #13 48 x 96 .092 .60 19.20 120 " " 24.00 72 x 96 " " 28.80 120 " " 36.00 96 x120 " " 48.00 1 1/2" – #10 48 x 96 .092 .79 25.28 120 " " 31.60 60 x120 " " 39.50 72 x 96 " " 37.92 120 " " 47.40 144 " " 56.68 1 1/2" – #9 36 x 96 .134 1.20 38.80 48 x 96 " " 38.40 120 " " 48.00 144 " " 57.60 60 x120 " " 60.00 72 x 96 " " 57.60 120 " " 72.00 144 " " 86.40 1 1/2" – #6 36 x 144 .198 2.50 90.00 48 x 96 " " 80.00 72 x 144 " " 180.00 2" – #10 36 x 96 .092 .68 16.32 120 " " 20.40 72 x 96 " " 32.64 120 " " 40.80 144 " " 48.96 2" – #9 36 x 96 .134 .90 21.60 120 " " 27.00 144 " " 32.40 48 x 96 " " 28.80 120 " " 36.00 144 " " 43.20 72 x 96 " " 43.20 120 " " 54.00 144 " " 64.80 *Style Designation—The first figure indicates the approximate width, the short way of the diamond, measuring from center to center of the bonds. Second figure indicates the approximate gauge of the sheet before expanding.

-

Flattened Expanded Metal

*Style Designation Width & Length (Inches) Thick. of Strand (Inches) Est. Wt., Lbs. Per Sq. Ft. Per Sheet 1/4" – #20 36 x 96 .030 .83 19.92 48 x 96 " " 26.56 1/4" – #18 48 x 96 .040 1.11 35.52 1/2" – #20 36 x 96 .029 .40 9.06 48 x 96 " " 12.80 1/2" – #18 36 x 96 .039 .66 15.84 120 " " 19.80 48 x 96 " " 21.12 120 " " 26.40 1/2" – #16 36 x 96 .050 .82 19.68 120 " " 24.60 144 " " 29.52 48 x 96 " " 26.24 120 " " 32.80 144 " " 39.36 60 x 96 " " 41.00 1/2" – #13 36 x 96 .070 1.40 33.60 120 " " 42.00 144 " " 50.40 48 x 96 " " 44.80 120 " " 56.00 144 " " 67.20 3/4" – #16 36 x 96 .048 .51 12.24 120 " " 15.30 144 " " 18.36 48 x 96 " " 16.32 120 " " 20.40 144 " " 24.48 3/4" – #14 36 x 96 .061 .63 15.12 48 x 96 " " 20.16 3/4" – #13 36 x 96 .070 .75 18.00 120 " " 22.50 144 " " 27.00 48 x 96 " " 24.00 120 " " 30.00 144 " " 36.00 3/4" – #9 36 x 96 .120 1.71 41.04 120 " " 51.30 144 " " 61.56 48 x 96 " " 54.72 120 " " 68.40 144 " " 82.08 60 x 96 " " 68.40 1" – #16 36 x 96 .050 .41 9.84 48 x 96 " " 13.12 1 1/2" – #16 36 x 96 .048 .38 9.12 120 " " 11.40 144 " " 13.68 48 x 96 " " 12.16 120 " " 15.20 144 " " 18.24 1 1/2" – #14 36 x96 .060 .46 11.04 48 x 96 " " 14.72 1 1/2" – #13 36 x 96 .070 .57 13.68 120 " " 17.10 144 " " 20.52 48 x 96 " " 18.24 120 " " 22.80 144 " " 27.36 60 x 120 " " 28.50 72 x 120 " " 34.20 1 1/2" – #9 36 x 96 .110 1.14 27.36 120 " " 34.20 144 " " 41.04 48 x 96 " " 36.48 120 " " 45.60 144 " " 54.72 *Style Designation—The first figure indicates the approximate width, the short way of the diamond, measuring from center to center of the bonds. Second figure indicates the approximate gauge of the sheet before expanding.

-

Expanded Metal Accessories

Information on request.

-

Expanded Metal Gratings

Expanded Metal Gratings are produced from heavy steel plate and provide an economical open flooring with the advantage of strength, durability, and light weight. Unlike solid flooring, Expanded Metal Gratings do not block light and air. Dirt, grease, snow, and mud cannot collect on the walking surface. Floors made from these gratings are attractive in appearance, and their non-slip quality is an important safety factor. Various styles are available, designed to support walking loads on clear spans up to five feet – longer with reinforcement. For further information, ask for our special pamphlet.

Style Designation Size in Inches Size of Mesh* in Inches Wt. Per Square Foot Width Length Treadway (Walkway) 48 x 96 1.412 4.00 4.27 72 x 96 " " " Hiwalk (Skywalk) 48 x 120 2.000 6.00 3.14 72 x120 " " " 3.0 Lb. Grating 48 x 96 1.333 5.33 3.00 120 " " " 60 x 120 " " " 72 x 96 1.440 5.00 " 120 " " " 144 " " " 150 1.333 5.33 " 4.0 Lb. Grating 48 x 96 " " 4.00 120 " " " 60 x 96 " " " 72 x 96 " " " 120 " " " 5.0 Lb. Grating 48 x 96 1.330 " 5.00 72 x 120 " " " 6.25 Lb. Grating 48 x 48 1.412 " 6.25 96 " " " 144 " " " 192 " " " 72 x 96 " " " 120 " " " * Measured center to center of bonds.

-

Welded—Riveted—Mechanical Lock

Gratings, Decking, Grilles, and Stair Treads

We represent various manufacturers of grating products which have been designed to fill many functional and ornamental architectural requirements. Such material offers the benefits of minimum weight, maximum carrying capacity, ventilation, sanitation, light admission, non-skid safety, and self-cleaning. We will be glad to furnish further information upon request.

-

Floor Plates

Stock Sizes

16 Ga. to 1/8"—As indicated below.

3/16” to 3/4"—Thickness and Widths as indicated below. Lengths up to 24’.

Thickness refers to body of plate, not including raised portion.

Stock Size Estimated Weight, Lbs. Per Sq. Ft. Per Lin. Ft. Per Plate 14 Ga. 48 x 96 3.75 15.00 120.0 120 " " 150.0 144 " " 180.0 12 Ga. 48 x 96 5.25 21.00 168.0 120 " " 210.0 144 " " 252.0 240 " " 420.0 60 x 96 " 26.25 210.0 120 " " 262.5 144 " " 315.0 240 " " 525.0 1/8 48 x 96 6.15 24.60 196.8 120 " " 246.0 144 " " 295.2 168 " " 344.4 192 " " 393.6 240 " " 492.0 288 " " 590.4 60 x 96 " 30.75 246.0 120 " " 307.5 144 " " 369.0 240 " " 615.0 288 " " 738.0 72 x 240 " 36.90 738.0 288 " " 885.6

Thickness and Width Estimated Weight, Lbs. Per Sq. Ft. Per Lin. Ft. 3/16 x 48 8.71 34.84 3/16 x 60 " 43.55 3/16 x 72 " 52.26 1/4 x 48 11.26 45.04 1/4 x 60 " 56.30 1/4 x 72 " 67.56 5/16 x 48 13.81 55.24 5/16 x 60 " 69.05 5/16 x 72 " 82.86 5/16 x 96 " 110.5 3/8 x 48 16.37 65.48 3/8 x 60 " 81.85 3/8 x 72 " 98.22 3/8 x 96 " 131.0 1/2 x 48 21.47 85.88 1/2 x 60 " 107.4 1/2 x 72 " 128.8 1/2 x 96 " 171.8 5/8 x 60 26.58 132.9 5/8 x 72 " 159.5 3/4 x 60 31.68 158.4 3/4 x 96 " 253.4

-

Standard Pipe Sizes and Weights

Wall Thicknesses and Weights per foot

Nominal Pipe Size Outsize Diameter (Inches) Schedule 5S Schedule 10S Schedule 40 & 40S STD Schedule 80 & 80S XS Schedule 160 XXS 1/8 .405 .068

S .2447

A .0847.095

S .3145

A .10081/4 .540 .088

S .4248

A .1470.119

S .5351

A .18513/8 .675 .091

S .5650

A .1955.126

S .7388

A .25561/2 .840 .083

S .6710

A .2321.109

S .8510

A .2944.147

S 1.088

A .3764.187

S 1.304

A .4511.294

S 1.714

A .59303/4 1.050 .113

S 1.131

A .3913.154

S 1.474

A .5100.218

S 1.937

A .6702.308

S 2.441

A .84451 1.315 .109

S 1.404

A .4857.133

S 1.679

A .5809.179

S 2.172

A .7515.250

S 2.844

A .9839.358

S 3.659

A 1.2661 1/4 1.660 .109

S 1.806

A .6248.140

S 2.273

A .7864.191

S 2.997

A 1.037.250

S 3.765

A 1.302.382

S 5.214

A 1.8041 1/2 1.900 .109

S 2.085

A .7214.147

S 2.718

A .9404.200

S 3.631

A 1.256.281

S 4.859

A 1.681.400

S 6.408

A 2.2172 2.375 .109

S 2.638

A .9127.154

S 3.653

A 1.264.218

S 5.022

A 1.737.343

S 7.444

A 2.575.436

S 9.029

A 3.1242 1/2 2.875 .120

S 3.531

A 1.221.203

S 5.793

A 2.004.276

S 7.661

A 2.650.375

S 10.01

A 3.464.552

S 13.70

A 4.7403 3.500 .120

S 4.332

A 1.498.216

S 7.576

A 2.621.300

S 10.25

A 3.547.438

S 14.32

A 4.945.600

S 18.58

A 6.4283 1/2 4.000 .120

S 4.973

A 1.720.226

S 9.109

A 3.151.318

S 12.51

A 4.326Nominal Pipe Size Outsize Diameter (Inches) Schedule 5S Schedule 10S Schedule 10 Schedule 20 Schedule 30 STD (Standard Wall) Schedule 40 4 4.500 .120

S 5.613

A 1.942.237

S 10.79

A 3.733.237

S 10.79

A 3.7335 5.563 .134

S 7.770

A 2.668.258

S 14.62

A 5.057.258

S 14.62

A 5.0576 6.625 .134

S 9.289

A 3.213.280

S 18.97

A 6.564.280

S 18.97

A 6.5648 8.625 .148

S 13.40

A 4.635.250

S 22.36

A 7.735.277

S 24.70

A 8.543.322

S 28.55

A 9.878.322

S 28.55

A 9.87810 10.750 . .165

S 18.65

A 6.453.250

S 28.04

A 9.698.307

S 34.24

A 11.84.365

S 40.48

A 14.00.365

S 40.48

A 14.0012 12.750 .180

S 24.16

A 8.359.375

S 49,56

A 17.15.406

S 53.52

A 18.5214 14.000 .375

S 54.57

A 18.88.375

S 54.57

A 18.88.438

S 63.44

A 21.9516 16.000 .375

S 62.58

A 21.65.375

S 62.58

A 21.65.500

S 82.77

A 28.6418 18.00 .438

S 82.15

A 28.42.562

S 104.7

A 36.2120 20.000 .593

S 122.9

A 42.5224 24.000 .687

S 171.1

A 59.1830 30.000

-

Hot Rolled Carbon Steel Plates

Sheared—Flame Cut

Color Marking: Corner striped blue

Hot Rolled Carbon Steel Plates are produced from basic oxygen process steel. The designations applied to this material are based upon the types of mills used to produce the plates and resulting edge conditions. SHEARED PLATES have been rolled between horizontal rolls, with edges and ends later trimmed by shearing to obtain rectangular shape. In the heavier thicknesses (generally over 1 1/2"), the trimming is accomplished by flame cutting—hence the designation FLAME CUT PLATES.

Specifications

Thickness Range Normally Stocked ASTM A 36 3/16"-16"

When material over 1 1/2" thick is used as bearing plates in structures other than bridges, ASTM A 36 applies.Analysis (ASTM A36)

C Max. Mn P Max. S Max. Si 3/4" & under .25 — .04 .05 — Over 3/4" to 1 1/2" .25 .80/1.20 .04 .05 —

Applications—Storage tanks, storage bins, welded pipe, bridge construction, freight and passenger cars, barges, tankers, machinery construction, mining cars and equipment, bearing plates for buildings, and other structural applications and various parts obtained by flame cutting with our modern shape cutting facilities.Mechanical Properties (Typical)

Tensile Strength (psi) Yield Strength (psi) Elongation in 8"* ASTM A 36 58/80,000 36,000 Min. 18% Min. * Subject to reduction for thicknesses under 5/16".

Machinability—Hot Rolled Carbon Plates have a machinability rating of approximately 72%, based on 1212 as 100%, with average surface cutting speed of 120 feet per minute. When considerable machining or drilling is to be performed, we recommend the use of Free-Cutting Plates.

Weldability—These plates are easily welded by all the welding processes and the resultant welds and joints are of extremely high quality. The grade of welding rod to be used depends on the thickness of section, design, service requirements, etc.

Stock Sizes

Sheared: Stocked in thicknesses from 3/16" to 1 1/2", widths up to 120", and lengths up to 480".

Flame cut: Stocked in thicknesses from 1 5/8" to 16". Maximum widths vary from 72" to 96", depending on thickness. Stock lengths are up to 360".

-

Free-Cutting Carbon Steel Plate

J-20 Carbon Plate

J-45 Carbon PlateColor Marking:

- J-20—Corner striped Black

- J-45—Corner striped White

J-20 and J-45 free-cutting carbon steel plates are made to EMJ’s own specifications in order to insure free-machining steel of uniformly high quality. Because of their outstanding machinability and excellent finishing characteristics, substantial savings are effected through use of these materials.

J-20 is a low-carbon analyses that may be carburized and hardened using the same treatments employed with ordinary low-carbon steels.

J-45 is a high-carbon analyses that may be hardened satisfactorily by direct-heating and quenching, flame hardening, or induction hardening.

Analysis (Typical)

Carbon Manganese Phosphorus Sulphur Silicon J-20 .20 1.25 .04 Max. .25 .20 J-45 .45 1.25 .04 Max. .25 .15 Applications—The low carbon grades are used for mechanical rubber molds, V-belt mold rings, gears, cams, sprockets, jigs and fixtures, templates, etc. The high carbon grades are used for rubber molds, short-run blanking and trimming dies, slides, racks, machine ways, spinning chucks, etc.

Mechanical Properties (Typical)—The following values are average and may be considered as representative of the grade:

Tensile Strength (psi) Yield Strength (psi) Elongation in 2" Reduction of Area Brinell Hardness Low Carbon Grades 72,000 48,000 30% 60% 149 High Carbon Grades 90,000 56,000 20% 40% 187 In thicker sections, properties are somewhat lower.

Machinability—These steels are machinable at speeds up to 40% higher than other steels with comparable carbon content. J-20 is machined at cutting speeds up to 170 surface feet per minute. J-45 is machined at cutting speeds up to 145 surface feet per minute. Flame cutting of the high carbon grades produces a hardening effect on the cut edge which may be minimized by stress relieving.

Weldability—These free machining steels are not generally recommended for welding. They can be welded using the proper techniques and electrodes. Low-hydrogen electrodes are recommended to avoid excessive porosity and under-bead cracking that is likely to occur with the use of cellulose-covered rods. American Welding Society Classes EXX16 or EXX18 should be used with the tensile strength class determined by the strength desired. Current control is critical, and amperage should be regulated to obtain adequate fluidity of the weld metal and yet minimize dilution of the weld metal by the parent metal. The high carbon grades should be preheated to 350o-450o prior to welding and stress-relieved or normalized (see below) immediately after welding.

Hardening—J-20 responds to any of the standard carburizing and subsequent hardening methods used for such grades as 1018. J-45 responds to any of the standard treatments used for such grades as 1144.

J-20 J-45 Normalize 1650°-1750° F 1600°-1700° F Anneal 1550°-1600° F 1450°-1500° F Stress Relieve 1250°-1300° F 1200°-1300° F Carburize 1650°-1700° F — Harden 1450°-1500° F (water) 1475°-1550° F (oil or water) "J-20" and "J-45" are trademarks of Earle M. Jorgensen Co.

Stock Sizes

These plates are stocked in thicknesses from 1/4" to 6". Most thicknesses are carried in widths up to 96" and lengths up to 240".

-

High Carbon Plates

Sheared—Flame Cut

UNS G10450Color Marking: 1045 As-Rolled—Corner striped Red

This high carbon grade possesses higher strength with good toughness than is found in low carbon plate. It has low hardenability which means that it can be fully hardened in thin sections only with a drastic quench. In heavier sections, partial hardening increases strength substantially, and flame or induction hardening pro- duces high surface hardness.

1045 has good wear and abrasion resistance which can be further improved by heat treatment.

Analysis

Carbon Manganese Phosphorus Sulphur 1045 .42/.50 .60/.90 .04 Max. .05 Max. Applications—The 1045 grade is generally used for gears, pinions, brake discs, wear plates, base plates, etc.

Mechanical Properties (Typical)—The following values are average and may be considered as representative of the grade:

Tensile Strength (psi) Yield Strength (psi) Elongation in 2" Reduction of Area Brinell Hardness 1045 As Rolled 95,000 56,000 21% 44% 197 Machinability—1045 As-Rolled—average cutting speed is 95 surface feet per minute. This is not free-machining steel and when considerable machining is to be performed, J-45 are the free-machining steel equivalents to 1045.

Weldability—High Carbon Plates may be welded with proper precautions. With thin sections and a flexible design, gas or arc welding may be used without preheating; but in joints over 3/8” thick preheating is necessary. To develop equivalent strength in a weld, a low alloy filler is recommended. Stress relieving is also recommended. The grade of welding rod to be used depends on the thickness of section, design, service requirements, etc.

Hardening—This Grade is essentially a water-hardening steel, but may be quenched in oil.

1045 Normalize 1600°-1700° F Anneal 1400°-1500° F Hardening 1475°-1550° F Temper To Desired Hardness

Stock Sizes

High Carbon Plates are stocked in thicknesses from 3/16" to 14", widths up to 96", and lengths up to 30 feet.

-

Pressure Vessel Quality Plates

These are hot rolled carbon steel plates produced by the basic oxygen process. They are high quality products which meet ASTM and ASME specifications, as well as those of the Hartford Steam Boiler Inspection and Insurance Co. They have been rigidly inspected and tested to insure quality satisfactory for pressure vessels.

Specifications and Color Marking

ASTM Specification Color Marking (Corner Stripe) Pressure Vessel Quality ASTM A 285, Grade C Yellow ASTM A 515, Grade 70 Purple ASTM A 516, Grade 70 Black & Pink Analysis

Carbon Max. Manganese Phosphorus Max. Sulphur Max. Silicon A 285, Grade C .28 .90 Max. .035 .04 — A 515, Grade 70 1" thick and under .31 1.20 Max. .035 .04 .15/.40 Over 1" and 2" incl .33 1.20 Max. .035 .04 .15/.40 Over 2" and 8" incl .35 1.20 Max. .035 .04 .15/.40 A 516, Grade 70 1/2" thick & under .27 .85/1.20 .035 .04 .15/.40 Over 1/2" to 2" incl .28 .85/1.20 .035 .04 .15/.40 Over 2" to 4" incl .30 .85/1.20 .035 .04 .15/.40 Over 4" to 8" incl .31 .85/1.20 .035 .04 .15/.40 Applications

ASTM A 285 covers plates of low and intermediate tensile strengths for pressure vessels. The maximum thickness of plates produced to this specification is 2".

ASTM A 515 covers a course grain carbon silicon steel intended for intermediate or high temperature service in boilers and other pressure vessels.

ASTM A 516 covers a fine grain carbon manganese silicon steel intended for service in pressure vessels at temperatures where improved notch toughness is important.

Material for all three specifications is intended for fusion welding where the welding technique is of prime importance with welding procedure accomplished under approved methods.

Mechanical Properties

Tensile Strength (psi) Yield Strength (psi) Elongation in 8" A 285, Grade C 55,000/75,000 30,000 Min. 23% Min.* A 515 and A 516, Grade 70 70,000/90,000 38,000 Min. 17% Min. Subject to modification for thicknesses under 5/16" and over 3/4".

Machinability—Although not considered free-machining, these grades can be surface machined or drilled readily.

Weldability—These grades are easily welded by all welding processes although they are intended for fusion welding. The resultant welds are of high quality, when the welding procedure is accomplished under approved methods.

Stock Sizes

Pressure Vessel Quality Plates are stocked in thicknesses from 3/16" to 8", widths up to 96", and lengths up to 336".

-

Floor Plate

ASTM A 768

Floor Plate provides maximum skid resistance regardless of how the plate is laid or the angle from which it is approached. Patterns are continuous whether adjoining plates are laid end to end, side to side, or side to end. Cutting waste is reduced to a minimum. Cleaning is easily accomplished with a hose, brush, or mop, with rapid and complete drainage.

Analysis

Carbon Manganese Phosphorus Sulphur .10/.25 .30/.70 .05 Approx. .05 Approx. Applications—Running board steps, floors, walkways, platforms, cover plates, stair treads, hatch covers, trench covers, truck runways, conveyors, etc.

Mechanical Properties—Floor Plates are not normally used as main stress-carrying members and are seldom specified to tensile requirement. However, properties are approximately as follows:

Tensile Strength (psi) Yield Strength (psi) Elongation in 8" 60,000 33,000 22% Machinability—Can be machine or drilled readily.

Weldability—Easily welded by all the welding process, and the resultant welds are of extremely good quality. The grade of welding rod to be used depends on the thickness of section, design, service requirements, etc.

-

Hot Rolled Sheets and Hot Rolled Pickled & Oiled Sheets

ASTM A 1011

(Formerly ASTM A 569 and A 570)Hot Rolled Commercial Quality Sheets are produced from low carbon rimming, capped, or semi-killed steel, and are intended for uses involving simple bending or moderate drawing and welding. They may be bent flat on themselves in any direction at room temperature without cracking on the outside of the bent portion.

The Pickled and Oiled Sheets should be used when the tight oxide scale present on Hot Rolled Sheets is objectionable.

Analysis

C Mn P S Cu Ni Cr Mo V Cb 0.25 0.90 0.035 0.040 .20 .20 0.15 0.06 0.008 0.008 Applications—Hot Rolled Commercial Quality Sheets are used for a variety of applications from agricultural implements to automotive equipment, from blower and ventilating systems to hot air registers, from stub barrels and drums to bins and partitions. Pickled and Oiled Sheets with their superior smooth surface are recommended for stamping and ordinary drawing applications. After cleaning, they can be painted or enameled.

Hot Rolled Sheets may be used for structural applications.

Mechanical Properties—The following minimum properties apply to ASTM A570, grades 30 and 33:

Elongation in 2" Tensile Strength (psi) Yield Strength (psi) .0255" to .0635" .0636" to .0971" .0972" to .2299" Grade 30 49,000 30,000 21.0% 24.0% 25.0% Grade 33 52,000 33,000 18.0% 22.0% 25.0% Hot Rolled Sheets and

Pickled & Oiled SheetsGauge Width and Length Est. Wt. Lbs. Per Sheet 16 Ga.—(.0598") 2.5 Lb. Sq. Ft. 30 x 96 50.00 120 62.50 144 75.00 36 x 96 60.00 120 75.00 144 90.00 42 x 96 70.00 120 87.50 144 105.00 48 x 96 80.00 120 100.00 144 120.00 240 200.00 54 x 120 112.50 60 x 96 100.00 120 125.00 144 150.00 14 Ga.—(.0747”) 3.125 Lb. Sq. Ft. 36 x 96 75.00 120 93.75 144 112.50 42 x 96 87.50 120 109.38 144 131.25 48 x 96 100.00 120 125.00 144 150.00 48 x 240 250.00 54 x 96 112.50 120 140.63 60 x 96 125.00 120 156.25 144 187.50 240 312.50 72 x 120 187.50 144 225.00 240 375.00 13 Ga.—(.0897") 3.75 Lb. Sq. Ft. 36 x 96 90.00 120 112.50 48 x 96 120.00 120 150.00 12 Ga.—(.1046") 4.375 Lb. Sq. Ft. 36 x 96 105.00 120 131.25 144 157.70 42 x 96 122.50 120 153.13 48 x 96 140.00 120 175.00 144 210.00 240 350.00 54 x 96 157.50 120 196.88 60 x 96 175.00 120 218.75 144 262.50 192 350.00 240 437.50 72 x 96 210.00 120 262.50 144 315.00 192 420.00 240 525.00 84 x 120 306.25 144 367.50 11 Ga.—(.1196") 5.0 Lb. Sq. Ft. 36 x 96 120.00 120 150.00 144 180.00 48 x 96 160.00 48 x 120 200.00 144 240.00 240 400.00 60 x 96 200.00 120 250.00 144 300.00 240 500.00 72 x 96 240.00 120 300.00 144 360.00 240 600.00 10 Ga.—(.1345") 5.625 Lb. Sq. Ft. 36 x 96 135.00 120 168.75 144 202.50 240 337.50 42 x 96 157.50 120 196.88 144 236.25 48 x 96 180.00 120 225.00 144 270.00 240 450.00 60 x 96 225.00 120 281.25 144 337.50 240 562.50 72 x 96 270.00 120 337.50 144 405.00 240 675.00 7 Ga.—(.1793") 7.5 Lb. Sq. Ft. 36 x 96 180.00 120 225.00 144 270.00 48 x 96 240.00 120 300.00 144 360.00 240 600.00 60 x 96 300.00 120 375.00 144 450.00 240 750.00 72 x 120 450.00 144 540.00 240 900.00

-

Cold Rolled Sheets—ASTM A 1008

(Formerly ASTM A 366 — Commercial Quality)

(Formerly ASTM A 620 — Drawing Quality)Cold Rolled Commercial Quality Sheets are produced from rimming, capped, or semi-killed steel and are intended for exposed or unexposed parts involving bending, moderate drawing or forming and welding. They may be bent flat on themselves in any direction without cracking.

Cold Rolled Drawing Quality Sheets are produced from special killed steels, and are intended for parts involving severe forming or drawing. Sheets of this quality have a greater degree of ductility and are more consistent in performance because of higher standards in production, selection, and processing of the steel. The surface finish is a dull matte texture.

Analysis

Carbon Manganese Phosphorus Sulphur Commercial Quality .15 Max. .60 Max. .035 Max. .040 Max. Drawing Quality .10 Max. .50 Max. .025 Max. .035 Max. Applications—Practical experience is usually sufficient to determine whether Commercial Quality of Drawing Quality is required for a given part. Where experience is not adequate, the Scribed Square Test (ASTM A 568) can prove helpful. A grid of one inch squares is marked on the section representing the most severe draw. The squares are measured for percent increase in area after drawing. Experience has shown that Commercial Quality is usually satisfactory if the increase in area is less than 25%. If more than 25%, Drawing Quality is recommended.

Cold Rolled Sheets

Ga. Width and Length Est. Wt. Lbs. Per Sheet 28 Ga.—(.0149") .625 Lb. Sq. Ft. 36 x 96 15.00 120 18.75 26 Ga.—(.0179") .75 Lb. Sq. Ft. 36 x 96 18.00 120 22.50 42 x 96 21.00 120 26.25 48 x 96 24.00 120 30.00 52 x 120 32.50 24 Ga.—(.0239") 1.0 Lb. Sq. Ft. 36 x 96 24.00 120 30.00 48x96 32.00 120 40.00 22 Ga.—(.0299") 1.25 Lb. Sq. Ft. 30 x 120 31.25 36 x 96 30.00 120 37.50 48 x 96 40.00 120 50.00 144 60.00 20 Ga.—(.0359") 1.5 Lb. Sq. Ft. 30 x 96 30.00 120 37.50 36 x 96 36.00 120 45.00 144 54.00 156 58.50 42 x 120 52.50 144 63.00 48 x 96 48.00 120 60.00 144 72.00 60 x 120 75.00 144 90.00 18 Ga.—(.0478") 2.0 Lb. Sq. Ft. 36 x 96 48.00 120 60.00 144 72.00 42 x 120 70.00 144 84.00 48 x 96 64.00 120 80.00 144 96.00 60 x 120 100.00 144 120.00 16 Ga.—(.0598") 2.5 Lb. Sq. Ft. 30 x 96 50.00 36 x 96 60.00 120 75.00 144 90.00 42 x 120 87.50 144 105.00 48 x 96 80.00 120 100.00 144 120.00 60 x 96 100.00 120 125.00 144 150.00 72 x 144 180.00 14 Ga.—(.0747") 3.125 Lb. Sq. Ft. 30 x 120 78.13 36 x 96 75.00 120 93.75 42 x 120 109.38 48 x 96 100.00 120 125.00 144 150.00 192 200.00 54 x 120 140.63 60 x 120 156.25 144 187.50 72 x 120 187.50 144 225.00 13 Ga.—(.0897") 3.75 Lb. Sq. Ft. 36 x 96 90.00 120 112.50 48 x 96 120.00 120 150.00 60 x 96 150.00 12 Ga.—(.1046") 4.375 Lb. Sq. Ft. 36 x 96 105.00 120 131.25 48 x 96 140.00 120 175.00 144 210.00 60 x 120 218.75 144 262.50 72 x 120 262.50 144 315.00 11 Ga.—(.1196") 5.0 Lb. Sq. Ft. 36 x 90 120.00 120 150.00 48 x 96 160.00 120 200.00 144 240.00 60 x 120 250.00 144 300.00 72 x 120 300.00 10 Ga.—(.1345") 5.625 Lb. Sq. Ft. 36 x 120 168.75 48 x 96 180.00 120 225.00

-

Flat Galvanized Sheets

ASTM A 653

(Formerly ASTM Specifications: A 526, A527)These sheets are produced from rimming, capped, or semi-killed steel, and are intended for uses involving simple bending or moderate forming. They may be bent flat on themselves in any direction at room temperature without cracking. The zinc coating will withstand bending without flaking when tested in accordance with ASTM A 525. The coating is applied by the continuous hot-dip process, producing a tight coat of prime spelter of the 1.25 oz. per square foot coating class.

Sheets meet the Commercial Quality requirements of ASTM A 526. Gauges 16 and lighter are available as Lock Forming Quality, conforming to ASTM A 527.

Analysis

Carbon Manganese Phosphorus Sulphur .15 Max. .60 Max. .035 Max. .04 Max. Applications—These sheets are for general utility uses such as corrugated siding and roofing, culverts, window frames, heating and ventilating ducting, cornices, eave troughs, etc. Galvanized sheets are sometimes painted, but when a superior paint retaining surface is desired, we recommend the use of Electrolytic Zinc Coated Sheets, for which see Page 6 of this section.

Flat Galvanized Sheets

Gauge Width and Length Est. Wt. Lbs. Per Sheet 30 Ga.—(.016") .656 Lb. Sq. Ft. 30 x 96 13.12 120 16.41 36 x 96 15.75 120 19.69 28 Ga—(.019") .781 Lb. Sq. Ft. 24 x 96 12.50 30 x 96 15.62 120 19.53 36 x 96 18.75 120 23.40 144 28.12 48 x 120 31.24 26 Ga—(.022") .906 Lb. Sq. Ft. 24 x 96 14.50 30 x 96 18.12 120 22.66 144 27.19 36 x 96 21.75 120 27.19 144 32.63 48 x 96 29.00 120 36.24 144 43.49 24 Ga—(.028") 1.156 Lb. Sq. Ft. 24 x 96 18.50 30 x 96 23.12 120 28.01 36 x 96 27.75 120 28.91 48 x 96 36.99 120 46.24 144 55.49 22 Ga—(.034") 1.406 Lb. Sq. Ft. 30 x 96 28.12 120 35.16 36 x 96 33.75 120 42.19 144 50.62 48 x 96 44.99 120 56.24 144 67.49 20 Ga—(.040") 1.656 Lb. Sq. Ft. 30 x 96 33.12 120 41.41 144 49.68 36 x 96 39.75 120 49.68 144 59.62 48 x 96 52.99 120 66.24 144 79.48 60 x 120 82.80 18 Ga—(.052") 2.156 Lb. Sq. Ft. 30 x 96 43.12 120 53.91 144 64.69 36 x 96 51.75 120 64.69 144 77.62 48 x 96 68.00 120 86.24 144 103.48 60 x 120 107.80 144 129.36 16 Ga—(.064") 2.656 Lb. Sq. Ft. 30 x 96 53.12 120 66.41 144 79.69 36 x 96 63.75 120 79.69 144 95.63 48 x 96 84.99 120 106.24 144 127.49 60 x 120 132.80 144 159.36 14 Ga—(.079") 3.281 Lb. Sq. Ft. 36 x 96 78.75 120 98.44 144 118.12 48 x 96 104.99 120 131.24 144 157.49 60 x 120 164.05 144 196.86 12 Ga—(.108") 4.531 Lb. Sq. Ft. 36 x 96 108.75 120 135.94 48 x 96 144.99 120 181.24 144 217.49 60 x 120 226.55 11 Ga—(.123") 5.156 Lb. Sq. Ft. 48 x 96 164.99 120 206.24 144 247.49 10 Ga—(.138") 5.781 Lb. Sq. Ft. 36 x 96 138.74 120 173.40 48 x 96 185.00 120 231.24 144 277.50 60 x 144 346.86 The thickness in inches shown above for the respective gauges are only approximate because Galvanized Sheets are produced to specified weights—not to specified thicknesses.

-

Electrolytic Zinc Coated Sheets

Electrolytic Zinc Coated Sheets have been developed to fulfill the need for a perfect paint bonding surface that has not been entirely satisfied by galvanized sheets produced by the hot-dip process. The zinc coating is applied by an electro-plating process that leaves a thin, uniform layer of zinc, followed by a phosphate coat bonderizing treatment.

Electrolytic Zinc Coated Sheets offer good protection against corrosion, and the specially treated surface provides excellent paint adherence without the need for costly cleaning and preparing operations. In addition, they are easily formed by such processes as spinning, deep drawing, and roll forming without danger of peeling or flaking of the zinc coating.

Applications—These sheets are recommended for applications that require painting, enameling, or lacquering, such as vending machines, office furniture, appliances, cabinets, truck and trailer bodies, shower cabinets, etc.

Gauge Width and Length Est. Wt. Lbs. Per Sheet 26 Ga.—(.0179") 0.75 Lb. Sq. Ft. 48 x 96 24.00 120 30.00 24 Ga.—(.0239") 1.0 Lb. Sq. Ft. 30 x 120 25.00 144 30.00 36 x 120 30.00 48 x 96 32.00 120 40.00 144 48.00 22 Ga.—(.0299") 1.25 Lb. Sq. Ft. 36 x 90 30.00 120 37.50 144 45.00 48 x 96 40.00 120 50.00 144 60.00 20 Ga.—(.0359") 1.50 Lb. Sq. Ft. 36 x 96 36.00 120 45.00 144 54.00 48 x 96 48.00 120 60.00 144 72.00 18 Ga.—(.0478") 2.0 Lb. Sq. Ft. 36 x 120 60.00 48 x 96 64.00 120 80.00 144 96.00 60 x 120 100.00 16 Ga.—(.0598") 2.5 Lb. Sq. Ft. 36 x 120 75.00 48 x 120 100.00 60 x 120 125.00

-

Square and Rectangular Steel Structural Tubing

Structural Tubing is available in steel and aluminum in a wide range of sizes in round, square and rectangular shapes. It has become a most important basic section for structural applications because of its adaptability to such varied uses. For stock sizes of Square and Rectangle Steel Structural Tubing, refer to Pages 109-112 and Square and Rectangular Aluminum Tubing, refer to Pages 92-93 of this section.

Structural tubing is an efficient structural member with many inherent advantages, including strength and lightness. For example, for a given weight the round section distributes stresses in compression and vertical loading equally and in all directions. In torsion it is capable of carrying a greater load than any other structural member of equal weight. Where there is uneven loading, rectangular sections may be used.

Structural Steel Tubing

Structural Steel Tubing is made from flat rolled basic oxygen steel, which is formed into a tubular shape and then welded by the electric resistance process. In this continuous welding process there is no loss of properties, and no irregularity that may be observed in the structure. Over the years, tests and service have demonstrated that the tube weld is as strong as the base metal. Structural Steel Tubing is available in two grades. Standard Structural Steel Tubing is the more common grade that is used for a variety of applications in many different industries. High Strength Structural is a higher strength grade that is used in more limited applications where further weight reduction is advantageous.Standard Structural Steel Tubing

Standard Structural Steel Tubing conforms to ASTM A 500. This specification cov- ers cold formed welded and seamless carbon steel structural tubing respectively. Following are minimum mechanical properties:Mechanical Properties—The following minimum mechanical properties apply:

Tensile Strength (psi) Yield Strength (psi) Elongation 2" Min. ASTM A 500 Grade A 45,000 33,000 25% Grade B 58,000 42,000 23% Grade C 62,000 46,000 21% Standard Structural Steel Tubing has the advantage of ease of fabrication, and all the standard fabrication techniques may be employed. it may be expanded or swaged, flattened or flared, bent or drawn. It may be mechanically joined or welded by all the commonly used techniques and practices.

High Strength Structural Steel Tubing

High Strength Structural Steel Tubing is higher in strength than the structural grade, allowing substantial weight reductions in design. With a minimum yield strength of 50,000 psi, this tubing has a high torque value. For many applications, its use results in lower cost than other tubing and structural shapes.High Strength Structural Tubing may be fabricated by all the standard techniques. It is easy to saw cut and drill. Flattening or flaring are best accomplished after heating. Welding may be performed with the ordinary techniques.

Tolerances For Square and Rectangular Structural Tubing

Outside Dimensions Tolerances

Largest Outside Dimension Across Flats, Inches Tolerance, plus and minus in Inches* 2 1/2 and under 0.020 Over 2 1/2 to 3 1/2 include 0.025 Over 3 1/2 to 5 1/2 include 0.030 Over 5 1/2 1% *Tolerances include allowance for convexity or concavity. Tolerance may be increased 50% when applied to the smaller dimension of rectangular sections whose ratio of the cross-sectional dimensions is between 1.5 and 3, and 100 percent when the ratio exceed 3.

Wall Thickness Tolerance

The tolerance for wall thickness exclusive of weld are shall be plus or minus 10% of the nominal wall thickness specified. The wall thickness is to be measured at the center of the flat.22 Feet and Under Over 22 Feet to 44 Feet include. Length Tolerance for Specified Mill Length (Inches) Over Under Over Under 1/2 1/4 3/4 1/4 Straightness Tolerance

The permissible variation for straightness shall be 1/8" times the number of feet of the total length divided by 5.Squareness of Sides

Adjacent sides may deviate from 90° by a tolerance of plus or minus 2° maximum.Radius of Corners

The radius of the outside corner of the section shall not exceed three times the specified wall thickness.Twist Tolerances

Specified Dimension of Longest Side Inches Maximum Twist in 3 Feet 1 1/2 and under 0.050" Over 1 1/2 to 2 1/2 include 0.062" Over 2 1/2 to 4 include 0.075" Over 4 to 6 include 0.087" Over 6 to 8 include 0.100" Over 8 0.112" Twist is measured by holding down one end of square or rectangular tube on a flat surface plate with the bottom side of the tube parallel to the surface plate and noting the height that either corner, at the opposite end of the bottom side of the tube, extends above the surface plate.

-

Square Steel Tubing

Outside Dimensions Wall Thickness Weight Per Foot 1/2 x 1/2 .049 .3005 .065 .3845 5/8 x 5/8 .049 .3838 .065 .4950 3/4 x 3/4 .049 .4671 .065 .6055 .083 .7530 .120 1.028 7/8 x 7/8 .049 .5504 .065 .7160 .083 .8940 .095 1.008 1 x 1 .049 .6337 .065 .8265 .072 .9090 .083 1.035 .095 1.169 .109 1.321 .120 1.436 1 1/8 x 1 1/8 .049 .7170 .065 .9370 .083 1.176 .095 1.331 .109 1.506 .120 1.640 1 1/4 x 1 1/4 .049 .8000 .065 1.047 .083 1.317 .095 1.492 .109 1.691 .120 1.844 .188 2.610 1 1/2 x 1 1/2 .049 .9670 .065 1.268 .083 1.599 .095 1.815 .109 2.062 .120 2.252 .134 2.489 .188 3.350 1 3/4 x 1 3/4 .049 1.134 .065 1.490 .083 1.882 .095 2.138 .109 2.432 .120 2.660 .134 2.945 2 x 2 .065 1.710 .083 2.164 .095 2.461 .109 2.830 .120 3.060 .134 3.401 .148 3.728 .188 4.320 .220 5.326 .250 5.410 2 1/4 x 2 1/4 .065 1.932 .083 2.446 .095 2.784 .109 3.174 .120 3.476 .134 3.856 .148 4.231 .180 5.067 2 1/2 x 2 1/2 .065 2.152 .083 2.728 .095 3.107 .109 3.580 .120 3.910 .134 4.312 .148 4.734 .188 5.610 .250 7.110 3 x 3 .065 2.594 .083 3.292 .095 3.753 .109 4.286 .120 4.700 .134 5.223 .188 6.870 .203 7.722 .250 8.810 .313 10.58 3 1/2 x 3 1/2 .083 3.857 .095 4.399 .109 5.027 .120 5.516 .125 5.610 .134 6.134 .148 6.747 .188 8.150 .250 10.51 .313 12.70 4 x 4 .083 4.422 .120 6.330 .188 9.450 .250 12.21 .313 14.83 .375 17.27 .500 21.63 4 1/2 x 4 1/2 .188 10.70 .250 13.91 5 x 5 .188 11.97 .250 15.62 .313 19.08 .375 22.37 .500 28.43 5 1/2 x 5 1/2 .188 13.25 .250 17.32 .313 21.21 .375 24.93 6 x 6 .188 14.56 .350 19.02 .313 23.34 .375 27.48 .500 35.24 7 x 7 .188 17.13 .250 22.42 .313 27.63 .375 32.58 .500 42.05 8 x 8 .188 19.63 .250 25.82 .313 31.84 .375 37.69 .500 48.85 9 x 9 .188 22.18 .250 29.23 .313 36.10 .375 55.66 .500 55.66 10 x 10 .188 24.73 .250 32.63 .375 47.90 .500 62.46 12 x 12 .188 29.84 .250 39.43 .375 58.10 .500 76.07

-

Rectangular Steel Tubing

Outside Dimensions Wall Thickness Weight Per Foot 1 x 1/2 .065 .6055 1 x 1 1/2 .049 .8000 .065 1.048 .083 1.317 .095 1.492 .109 1.691 .120 1.844 1 x 2 .065 1.269 .083 1.600 .095 1.815 .109 2.062 .120 2.252 1 x 2 1/2 .065 1.490 .083 1.882 .095 2.138 .109 2.443 .120 2.660 1 x 3 .065 1.711 .083 2.164 .095 2.461 .109 2.830 .120 3.060 1 x 3 1/2 .065 1.932 .083 2.446 .095 2.784 .109 3.174 .120 3.476 1 1/4 x 1/2 .065 .7160 1 1/4 x 2 .065 1.379 .083 1.741 .095 1.977 .109 2.247 .120 2.456 1 1/2 x 3/4 .065 .9370 .120 1.650 1 1/2 x 2 .065 1.490 .083 1.882 .095 2.138 .109 2.433 .120 2.660 1 1/2 x 2 1/2 .065 1.711 .083 2.164 .095 2.461 .109 2.803 .120 3.068 .134 3.401 .180 4.454 .188 4.490 .250 5.400 1 1/2 x 3 .065 1.932 .083 2.446 .095 2.784 .109 3.174 .120 3.476 .134 3.856 .148 4.231 .180 5.067 .188 5.070 1 1/2 x 3 1/2 .065 2.153 .083 2.728 .095 3.107 .109 3.544 .120 3.884 1 1/2 x 4 .065 2.374 .083 3.011 .095 3.430 .109 3.915 .120 4.292 .134 4.767 .148 5.237 .180 6.291 2 x 3 .065 2.153 .083 2.728 .095 3.107 .109 3.544 .120 3.884 .134 4.312 .148 4.734 .188 5.590 .250 7.110 2 x 4 .065 2.595 .083 3.293 .095 3.753 .109 4.286 .120 4.700 .134 5.223 .148 5.741 .188 6.870 .250 8.810 2 x 5 .109 5.027 .120 5.516 .134 6.134 .148 6.747 .188 8.150 .250 10.51 2 x 6 .188 9.420 .250 12.21 .313 14.83 2 x 8 .188 11.97 .250 15.62 .313 19.08 .375 22.37 2 x 10 .188 14.53 .250 19.02 .313 23.34 .375 27.48 2 x 12 .188 17.08 2 1/2 x 3 .065 2.374 .083 3.011 .095 3.430 .109 3.915 .120 4.292 .134 4.767 .148 5.237 .180 6.291 2 1/2 x 3 1/2 .065 2.595 .083 3.293 .095 3.753 .109 4.286 .120 4.700 .134 5.223 .148 5.741 .188 6.903 2 1/2 x 4 .083 3.575 .095 4.076 .109 4.656 .120 5.108 .134 5.679 .148 6.244 .180 7.515 2 1/2 x 5 .109 5.397 .120 5.924 .134 6.590 .148 7.250 .180 8.739 3 x 4 .083 3.857 .095 4.399 .109 5.027 .120 5.516 .134 6.134 .148 6.747 .188 8.150 .250 10.51 .313 12.70 3 x 5 .120 6.330 .188 9.420 .250 12.21 .313 14.83 .375 17.27 .500 21.63 3 x 6 .120 7.150 .188 10.70 .250 13.91 .375 19.82 3 x 7 .188 12.30 .250 15.62 .313 19.08 .375 22.37 3 x 8 .188 13.25 .250 17.32 .313 21.22 .375 24.93 3 x 9 .188 14.53 .250 19.02 .313 23.34 .375 27.48 3 x 10 .250 20.72 4 x 5 .188 10.70 .250 13.91 4 x 6 .188 11.97 .250 15.62 .313 19.08 .375 22.37 .500 28.43 4 x 7 .188 13.25 .250 17.32 .313 21.21 .375 24.93 4 x 8 .188 14.53 .250 19.02 .313 23.34 .375 27.48 .500 35.24 4 x 10 .188 17.08 .250 22.42 .313 27.59 .375 32.58 4 x 12 .188 19.63 .250 25.82 .313 31.84 .375 37.69 5 x 7 .188 14.53 .250 19.02 .313 23.34 .375 27.48 .500 35.24 5 x 9 .188 17.08 .250 22.42 .313 27.59 .375 32.58 5 x 10 .188 18.35 .250 24.12 6 x 8 .188 17.08 .250 22.42 .313 27.59 .375 32.58 .500 42.05 6 x 10 .188 19.63 .250 25.82 .313 31.84 .375 37.69 .500 48.85 6 x 12 .188 22.18 .250 29.23 .313 36.10 .375 42.79 .500 55.66 7 x 9 .188 19.63 .250 25.82 .313 31.84 .375 37.69 8 x 10 .375 42.79 .500 55.66